Thermal imagers

Thermal imagers (synonyms: FLIR, thermal camera, thermal imaging system, thermal viewer, thermovision) are the imaging systems sensitive to mid-wave and long-wave infrared radiation that generate images of the observed scenery using thermal radiation emitted by the scenery. They are one of crucial surveillance technologies for defense/security sector. These imagers have also found mass applications outside defense sector. Testing thermal imagers is needed for both manufacturers, maintenance workshops and final users for a set of different and important reasons. Hi-tech test equipment can help significantly in research development, manufacturing, maintenance, training, purchase optimization, and optimal use of these expensive imagers.

Thermal imagers are characterized using a long series of parameters. The most popular are: MRTD (Mimimal Resolvable Temperature Difference), NETD (Noise Equivalent Temperature Difference), MTF (Modulation Transfer Function), FOV (Field of View). The MRTD is a function ofa minimum temperature difference between the bars of the standard 4-bar target and the background required to resolve the thermal image of the bars by an observer versus spatial frequency of the target. NETD is a measure of high frequency temporal noise of image generated by tested thermal imager. MTF is a function that describe sharpness (blurring) of image generated by tested thermal imager. Finally, FOV is a parameter that describes maximal angular size of target that can be seen by tested imager. More detail definitions and measurement methods of parameters of thermal imagers are presented in Educational section.

Nowadays, thermal imagers are manufactured in big numbers in myriad of different types by a long series of manufacturers. They can be divided according to a series of different criterion: application (applications: surveillance or measurement), spectral band (MWIR or LWIR), sensor temperature (cooled or non cooled), field of view correlated to aperture of imager optics (from extremely narrow FOV below about 0.5° to extremely wide FOV over about 50°), image resolution (from about 160x120 or below to 1900x1200 pixels), format of electronic video signals (analog video or digital formats like ), type of display to present output image (external display or internal display), form of presentation of output optical image (thermal cameras, thermal sights, thermal clip ons).

It is not possible, or at least it is not feasable, to design a single universal systems for testing all thermal imagers offered on market that differ a lot from one imager to another imager. Therefore Inframet offers a long series of systems optimized for testing different groups of thermal imagers.

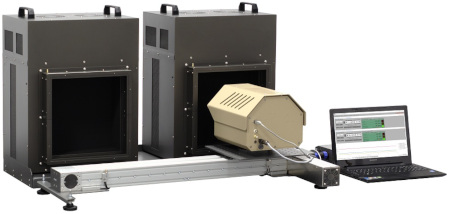

DT systems offered in a series of versions are the most popular Inframet systems for testing thermal imagers used in hundreds of laboratories worldwide including top world manufacturers. These test systems enable extensive testing of almost all thermal imagers available on the market. Imagers having optics of almost any focal lenght/aperture/FOV (including big long range narrow FOV thermal imagers for space application), generating output image in any electronic format, manufactured in almost any form can be tested. This quasi universality has been achieved by modular desing based on an idea to use a series of exchangeable modules (off axis parabolic collimators of different aperture, blackbodies, rotary wheels, sets of IR targets, frame grabbers, control software, and test software) to configure optimal test system for required application.

a)

|

b)

|

c)

|

|

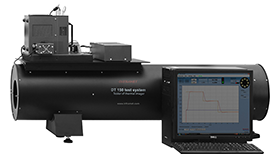

| Fig.1. Photos of several DT systems: a)DT150, b)DT110, c)DT400 | |

There are four main limitations of DT systems:

- DT systems are optimized for testing thermal imagers by analysis of electronic video signal. Direct analysis of optical image generated by imager display is not included.

- DT systems are high performance relatively expensive systems that offer expanded test capabilities (at least focusing, MRTD) when sometimes only very basic tests (focusing, resolution) are needed.

- DT systems due to modular design and use of reflective collimators of narrow FOV are not portable, not suitable for testing ultra wide FOV imagers, cannot simulate short distance targets, and are optimized for use in a laboratory/depot conditions.

- DT systems are optimized for testing surveillance thermal imagers. They are not optimized for testing measurement thermal imagers used for non contact temperature measurement.

Therefore Inframet offers also additional systems for testing thermal imagers that eliminates earlier listed limitations of DT systems. These new additional test systems are:

- TAIM - special version of DT system optimized for expanded testing small thermal sights and thermal clip ons,

- TAFT is mobile test station designed to enable basic testing surveillance thermal imagers at field/depot conditions,

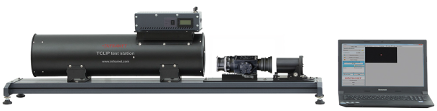

- TCLIP - system for basic testing of thermal clip ons that enables fast checking of proper aligning,

- DTR - system built using a refractive collimator optimized for testing small thermal imagers of very wide FOV,

- TSIM - simple, low cost system designed to enable only basic tests (focusing and resolution measurement) of thermal imagers,

- SAFT - small test system for testing measurement thermal imagers designed for short focus distance,

- TWAP - a portable wide angle projector optimized for testing imagers of medium/wide FOV,

- TFEV - modular professional system optimized for testing thermal imagers for fever screeing,

- TCAR - system for testing automotive thermal imagers.

a) |

b) |

c) |

d) |

e) |

f) |

g) |

h) |

i)  or

or

|

|

Fig.2. Photos of additional test systems: a)TAIM, b)TAFT, c)TCLIP, d)DTR, e)TSIM, f)SAFT,g)TWAP, h) TFEV, i)TCAR

NON UNIFORMITY CALIBRATION

Application of image procesing algorithm capable to correct spatial noise of IR FPA sensor of thermal imager is of critical importance to design themal imagers capable to generate near noise-free thermal image. Data needed to develop such algorithms is acquired during so called two point NUC (non uniformity correction) tests when imager to be calibrated can see a large blackbody that fills its FOV at two different blackbody temperatures. In case of advanced thermal imagers NUC tests are carried out at temperature chamber at different ambient temperatures that resemble real work conditions.

There are many low cost blackbodies offered on international market that can be used potentially for two point NUC applications. However, due to significant specular reflectivity, noticeable thermal uniformity, limited temporal stability, and lack of ability to work in temperature chambers these blackbodies are not suitable for professional applications. Inframet offers BNUC sets of blackbodies optimized for professional two point NUC applications.

Fig.3. Photo of BNUC-12D-2TCB-TC blackbody set

TESTING IR CAMERA CORES

Thermal camera core is an electronic modules capable to generate output thermal image in one of video image standards. It is built as a raw IR FPA sensor integrated with control/processing electronics. In simplification, thermal camera core can be understood as almost complete thermal imager without optics. Thermal camera cores are crucial blocks of thermal imagers built by combining camera core, optics and mechanical case. There are some companies who manufacture all these main blocks (camera core, optics and mechanical case) and later built thermal imagers. However, majority of thermal imagers offered at international market is built using thermal camera cores purchased from a dozen of main manufacturers. In such a situation problem of performance testing of thermal camera cores is of crucial importance for manufacturers of thermal imagers who work as system integrators. Test range is typically limited to measurement of NETD (noise equivalent temperature difference) that is that considered as a crucial parameter and is needed to verify quality of purchased camera cores. Other noise parameters like FPN, non-uniformity, 3D Noise model are sometimes measured, too. All these noise parameters of camera cores are measured and presented for a specific reference optics and this optics needs to be simulated during tests.

DTCORE is a set of tools designed for testing thermal camera cores. It is typically offered as an option for DT systems for testing thermal imagers. It offers measurement of following parameters: NETD, FPN, non-uniformity, 3D Noise model. The DTCORE is a modular set built from following modules: set of two OIM optics imitators, TCB-4D blackbody, PC set, analog video frame grabber, TCB Control program, TAS-N computer program. Set of OIM optics imitators is the crucial part of DTCORE. From design point of view OIM imitators are mechanical devices that precisely limit the cone where sensor of camera core gets irradiation from a large blackbody of variable temperature to value determined by F-number of simulated IR objective.

Fig.4. Photo of DTCORE set

Learn more:

- Data sheets: DT,TAIM, TSIM,DTR, TCLIP, TAFT, TFEV, TWAP, TCAR, SAFT , BNUC, DTCORE

- Recommendations on environmental conditions for Inframet test systems

- Educational section

- E-book: TESTING THERMAL IMAGERS

- Inframet Info section

- Inframet Newsletter

- Contact INFRAMET