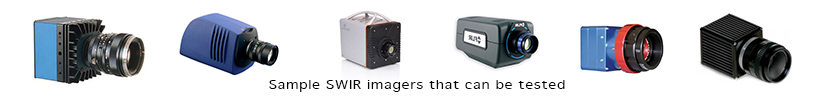

SWIR imagers

SWIR imagers (short wavelength infrared) are an important group of surveillance electro-optical imagers due several reasons. First, advances in InGaAs technology enabled design relatively low cost SWIR imagers. Second, InGaAs imagers are very sensitive and can generate images of observed scenery even at dark nights. Third, SWIR imagers are less vulnerable to bad atmospheric conditions than VIS-NIR cameras of NVDs working in visible/near infrared band. Fourth, SWIR imagers can generate hi-res images even if they are built using much smaller optics than used for design of thermal imagers. Fifth, SWIR imagers can see targets irradiated by typical laser range finders or designators that emits light in SWIR band.

Non cooled

SWIR imagers of spectral band up to 1700nm typically use radiation reflected by observed targets to create images of these targets similarly to

VIS-NIR cameras. Cooled SWIR imagers of expanded

spectral band up to about 2200nm used both reflected

light and thermal radiation emitted by observed hot targets. Due these features SWIR can be tested using both methodology for testing

VIS-NIR cameras or methodology for testing thermal imagers. Parameters of InGaAs FPAs can be also used to characterize SWIR imagers.

Inframet proposes to characterize SWIR imagers by three ways:

A)measurement of parameters typical for VIS-NIR cameras (Resolution, Minimal Resolvable Contrast, MTF, Distortion, FOV, Sensitivity, SNR, Noise Equivalent Input, Fixed Pattern Noise, Non Uniformity),

B) measurement of parameters typical for thermal imagers (MRT, MDT, MTF, NETD, FPN, non uniformity, distortion, FOV),

C) measurement of parameters of InGaAs FPA module at 1550 nm (Mean Detectivity, Noise Equivalent Irradiance, Noise, Dynamic range).

Limiting tests to measurement of only type A parameters

is acceptable in typical case of non-cooled SWIR cameras

sensitive up to about 1700nm. Expanded tests including

measurement of type B parameters are recommended in case

of cooled SWIR cameras sensitive up to 2200nm.

Fig. 1. ST200 test system for testing long range SWIR imagers |

Fig. 2. SINIS60 test system for testing short range SWIR imagers |

Fig. 2. SIWIR150 test system for basic radiometric testing/calibration SWIR imagers (two work modes) |

|

Inframet offers three types of test sytems for testing SWIR cameras:

ST test system is in general a variable target measuring system that uses a series of different targets to project their images into direction of a tested SWIR imager. The imager generates distorted copies of the projected images. Quality of the images generated by the imager is evaluated by human observers or by software and its important characteristics of SWIR imagers are measured. The ST test system consists of a reflective off axis collimator, broadband light source, medium temperature blackbody, motorized rotary wheel, a set of targets, a set of filters, PC, frame grabber, and test software.

SINIS system can be treated as a simplified version of ST system. It is based on manual halogen light source coded as LS-MAH-SW (non calibrated in basic version) in contrast to computerized calibrated SAL light source. Next, targets are manually inserted when in ST system targets are automatically exchanged using MRW-8 rotary wheel. Finally, SINIS is typically delivered as an image projector without PC and test software (it is assumed that these blocks are delivered by customer if needed). All these changes in design have enabled significant price reduction comparing to typical ST test system.

SIWIR is a system for basic testing/calibration of SWIR imagers/cores at production stage. It enables two groups of tests: 1) tests/calibration of SWIR imagers (core and optics and mechanical case), 2) tests/calibration of SWIR camera cores (image sensor and control electronics). In both cases the list of measured parameters of calibration function is the same: 1. Two point NUC, 2. Measurement of noise/sensitivity parameters (noise equivalent radiance NER in case of imagers or noise equivalent irradiance NEI in case of camera cores, 3. Measurement of spatial noise (non uniformity, fixed pattern noise) – option, 4. Measurement of relative spectral sensitivity (simplified measurement at several wavelengths) – option.

Learn more: