Optical tables

The primary goal of a well designed optical table is to eliminate vibrations of platform where the test system and tested system are located. These vibrations can cause relative motion between components of test system and tested system and such motion can generate measurement errors. Inframet offers two types of optical tables:

AT is a series of stationary optical tables manufactured by Inframet and optimized for use with Inframet test systems. The tables are built from two main blocks: 1) a support frame, 2) table plate. The support frame is made as a steel frame combined with rubber isolation absorbers. The table plate is made as thick ( 150 mm) multi-layer slab in external steel frame. In detail the multi-layer slab is composed by combining main layer of vertically bonded cores with top layer from artificial granite and with bottom cardboard layer. The table plate is characterized by excellent thermal stability and vibration damping properties. Typical sizes of AT tables are up to 1500 mm times 3000 mm. Bigger sizes are optionally possible.

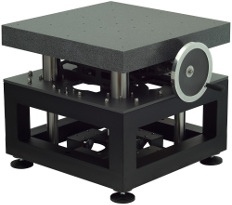

Fig. 1. Photo of AT1224 optical table (size 1200x2400mm)

The tests have shown that even in heavy industry buildings AT tables reduce vibrations to level not noticeable by even vibration sensitive test systems (like ORI test stations for testing optical objectives) and make measurement results not sensitive to acoustic vibrations in air, vibrations generated by moving mechanical parts in test system (like MRW 8 rotary wheel) or to vibrations transmitted from the building to the optical table through the table support.

MTAB is a series of mobile antivibration tables of regulated height of the platform. A set of wheels enables also easy horizontal movement. The table plate is made as a thick artificial granite slab in external steel frame. Height regulation at least 400mm.The table is characterized by excellent thermal stability and vibration damping properties.Typical table size is 700x700mm.The table is optimized for loads as high as 200kg.

The tests have shown that MTAB tables reduce vibrations to level not noticeable during test of electro-optical imaging and laser systems. MTAB is particularly useful when testing large and heavy multi sensor EO systems used for long range surveillance.

Learn more: