Night vision devices

Night vision devices are one of crucial surveillance technologies for defense/security sector. NVDs have also found mass applications outside defense sector. Modern night vision devices are divided into four basic types: night vision goggles, night vision monoculars, night vision sights, night vision binoculars. Each type of NVDs can be further divided according to type (generation) of image intensifier tubes used as a crucial module.

Due to historical reasons market of equipment for testing NVDs has been dominated for decades by miltary type, portable, non-computerized stations (suitcase type) that can be easily transported, used at field condtions at harsh environmental conditions but offer only limited test capabilities of only small NVDs (monoculars,goggles). Poor ergonomy, lack of abilitity to test/boresight of bigger NVDs (sights, clip-ons, periscopes), no computer archivisation are drawbacks of these test stations.

Test equipment for testing night vision devices manufactured by Inframet differs significantly from earlier described test stations. Majority of Inframet stations for testing NVDs have been designed as general application test equipment to be used mostly at depot/laboratory conditions. Therefore Inframet stations are bigger and , heavier. However, Inframet stations offer more expanded testing capabilities (more parameters can be measured), improved design (use of projection optics of not noticeable distortion, wider range of simulated light conditions), digital results archivisation (computerized stations), automatization of measurement of some parameters (dark spots), better ergonomy of work (desktop type stations), and higher test speed. Portable test station that offer basic test capabilities are offered, too.

Test stations manufactured by Inframet can be divided into seven groups:

- Stations for semi-automatic vertical configuration, desk type stations for semi-automatic testing of NVDs: NMAG;

- Quasi-universal, computerized, vertical configuration, desk type stations for expanded testing of NVDs: Nimax, Nicom,

- Universal horizontal configuration, table type stations for expanded testing/boresight of NVDs: Nivis, NVS,

- Mobile, non-computerized, vertical configuration stations for basic testing of some types of NVDs: NVT, NV14,

- Portable stations for basic tests at field conditions: NV20,NV10

- Stations for testing/boresight of special types of NVDs: N2PER, NCLIP,

- Additional tools: NIG, FORK, NPL, CCC, BCC, NCER.

|

|

|

| NIMAX | NICOM | |

|

||

| NIVIS | ||

|

|

|

| NVS | NVT | NV14 |

|

|

|

| NPER | NCLIP | |

|

|

|

| NV20 | NV10 | FORK |

|

|

|

| NPL | NIG | NCER |

|

|

|

| CCC | BCC | |

NMAG station is a new Inframet station that enables almost full automatic testing night vision devices. Operator duties are limited to positioning and focusing of tested NVD and pressing software button to start automatic test procedure.

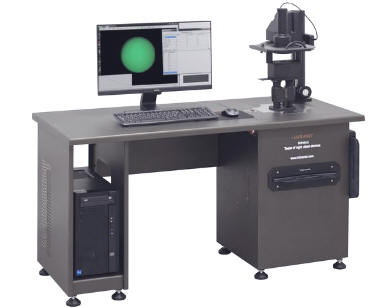

Nimax is a quasi-universal, computerized, ergonomic desk type station for expanded testing of NVDs. It enables testing great majority of NVDs: monoculars, goggles, and sights/binoculars of optics up to 120mm. All important parameters of NVDs listed earlier can be measured. The station is designed using desk type concept that enables ergonomic work and easy aligning of tested NVD and high test speed. The station is computerized: output image on external monitor, automatic calculation of dark spots, software support for resolution/MRC measurement, higher accuracy of FOV and distortion measurement, ability to measure MTF, computer read out of light source settings, digital recording of measurement results. The limitations: 1)Collimator maximal aperture is 120mm, 2) Typical mechanical railways of stable position are not used to connect tested NVD to the station. The consequences: 1) Big nigh vision sights of aperture over 120mm cannot be tested, 2)night vision sights can be tested but with exception of measurement of boresight angle to a reference mechanical axis, 3)night clip ons and periscopes cannot be tested. Therefore Nimax is a perfect choice when only monoculars and goggles are to be tested. It can be also used for testing night vision sights but without boresight tests.

Nicom is a simplified version of Nimax. It can be used for testing monoculars, goggles, and small sights/binoculars of optics of aperture up to about 70mm.

Nivis is an universal (most expanded version), computerized, table type station for expanded testing/boresight of NVDs. It enables testing all types of NVDs: monoculars, goggles, sights, binoculars, clip ons and periscopers of optics up to 150mm. All important parameters of NVDs listed earlier can be measured. Tested NVDs can be fixed using universal adapters (fast easy connection) or mechanical railway (typicaly Picatinny rail) for precision positioning. The station is computerized and offers the same features as Nimax or Nicom. It can be treated as a fusion of several specialized stations: NVS, NCLIP, and NPER.

NVS is a semi-universal non-computerized station of horizontal configuration for expanded testing/boresight of majority of NVDs: monoculars, goggles, and sights/binoculars of optics up to 150mm. It is a modular station where modules are located on an horizontal table. The main advantage is simplicity of operation in traditional ways preferred by conservative test teams. It enables both expanded testing and boresight (including boresight to a reference mechanical axis).

NVT is a mobile, non-computerized, vertical configuration station for basic testing of nigh vision monoculars/goggles of wide FOV about 40° (magnification equal to one). Vertical configuration station enable easy fast positioning of tested NVDs (gravity force helps to keep tested NVD stable).

NV14 is a mobile, non-computerized, vertical configuration station for basic testing of nigh vision monoculars/goggles of magnification equal to one and small sights of magnification up to about four (max optical aperture about 60mm). It can be treated as modified version of NVT (design based on bigger internal collimator) in order to enable tests of small sights (optics of aperture up to about 60mm).

NPER is a specialized station optimized for testing night vision periscopes. Both two types of night vision periscopes (driver binocular night vision periscopes for drivers of wide FOV and commander binocular/monocular night vision periscopes of narrow FOV).

NCLIP is a specialized station optimized for basic boresight/testing of night vision clip ons: measurement of deflection angle, rotation angle, and resolution.

NV20 is a portable test station for basic checks of binocular night vision googles at field conditions. In sharp contrast to competing solutions NV20 enables to carry out all critical checks to be done before start of important missions.

NV10 is a small portable test station optimized to carry out very basic tests of NVDs (monoculars, monocular goggles, binocular goggles) before important missions.

NIG is a portable station for measurement of brightness gain of night vision goggles/monoculars and optionally current consumption of battery of these devices. NIG station enables also to regulate power voltage applied to tested NVD and to check its performance in typical voltage range.

FORK is a professional station for testing automatic breakaway mechanisms of aviator NVGs. The station enables stabilization of tested NVGs to a horizontal platform, precision increasing of force in vertical direction applied to mechanical center of the goggles, and measurement of force when break way mechanism is activated.

NPL station enables performing nitrogen purge, fill up and leak test of night vision devices. These functionalities are needed during assembling, maintenance and repairing of night vision devices in order keep the interior parts dry and clean.

NCER is simple simulator of binocular NVGs with collimation defect that is buit in form of special photometric glasses.

CCC tester is a lightweight, mobile DC power supply that can measure current consumption of Night Vision Devices. This universal tester allows to measure current consumption at regulated voltage, simulating the standard power supply of NVD from battery.

BCC tester is a lightweight, mobile tester of batteries used to power Night Vision Devices. This universal tester allows to measure battery voltage at regulated power consumption. This measurement is possible to be done in laboratory conditions using typical multimeters and night vision device.

Tests of NVDs are typically done using guidelines from a long series of US defense standards (often called military standard or MIL standards). Nowadays, MIL standards are at least partially accepted by both manufacturers, test laboratories and final users of NVDs all over the world. Typical parameters to be measured are: resolution (center, peripheral, high light level), screen quality (dark spots), system gain, FOV, collimation errors, gain disparity, distortion, Minimum Resolvable Contrast, magnification, diopter range. Detail review of night vision technology and night vision metrology is presented in Educational section.

Learn more: